Meta Nqe lus piav qhia: Tshawb xyuas cov txheej txheem txhaj tshuaj molding siab tshaj plaws rau lub tsheb taub hau pwm pwm. Kawm txog kev xaiv cov khoom siv, kev tsim qauv zoo, thiab cov qauv kev ruaj ntseg hauv kev tsim tsheb teeb.

Taw qhia

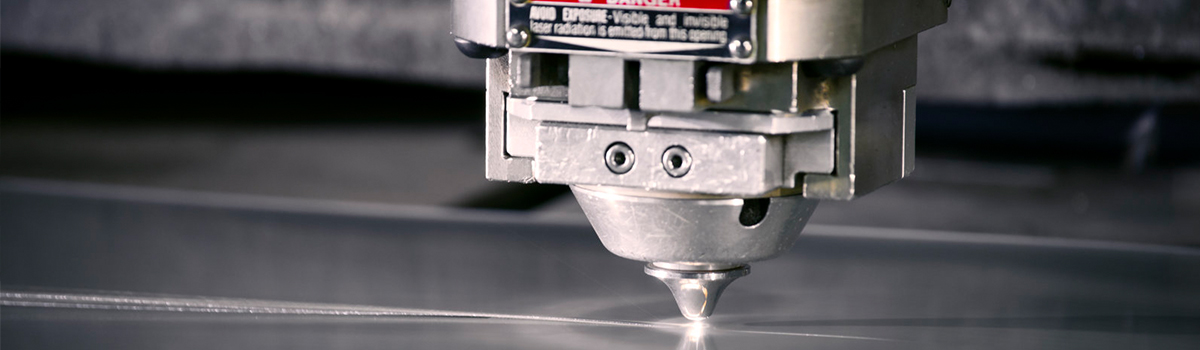

Kev lag luam tsheb teeb pom kev lag luam xav tau qhov tseeb heev, nrog lub teeb taub hau pwm yuav tsum tau ua siab ntev hauv qab 0.02mm. Raws li lub tsheb tsim tau hloov zuj zus mus rau slimmer LED arrays thiab adaptive tsav beams, txhaj pwm engineers ntsib cov teeb meem uas tsis tau muaj dua. Phau ntawv qhia no rhuav tshem cov txheej txheem tseem ceeb thiab cov tswv yim txiav-ntug dominating lub teb.

1. Kev xaiv cov khoom siv: Sib npaug Optics & Durability

Cov ntsiab lus tseem ceeb: polycarbonate txhaj tshuaj molding rau lub teeb taub hau, automotive-qib thermoplastics *

- PC (Polycarbonate): 90% ntawm lub teeb taub hau niaj hnub siv PC rau nws 89% lub teeb kis tau tus mob thiab 140 ° C kub tsis kam.

- PMMA Lenses: Qhov thib ob lo ntsiab muag feem ntau ua ke PMMA rau khawb tsis kam.

- Additives Matter: 0.3-0.5% UV stabilizers tiv thaiv yellowing; anti-fog agents txo cov condensation sab hauv.

Cov Lus Qhia Pro: BASF's Lexan SLX thiab Covestro's Makrolon AL muab kev ua kom zoo dua rau cov kav dej sib txuas.

2. Core-Cavity Design: Tackling Thin-Wall Challenges

Cov ntsiab lus tseem ceeb: nyias-phab ntsa headlight pwm tsim, automotive teeb txias raws *

- Phab ntsa Thickness: 1.2-2.5mm phab ntsa yuav tsum tau txhaj tshuaj ceev ceev (800-1,200 mm / sec) los tiv thaiv cov cim tsis txaus ntseeg.

- Conformal Cooling: 3D-luam tooj liab hlau channel txhim kho kev ua haujlwm txias los ntawm 40%, txo lub sijhawm voj voog.

- Nto Finishes: VDI 18-21 (textured) rau diffusers vs. SPI A1 (daim iav) kom pom tseeb.

Case Study: Tesla Model 3 matrix LED module ua tiav 0.005mm warpage siv gradient kub tswj.

3. Cov Txheej Txheem Txheej Txheem: Cov ntaub ntawv-tsav kom zoo

Cov ntsiab lus tseem ceeb: kev txhaj tshuaj molding tsis tau rau lub tsheb teeb, automotive teeb pwm validation *

| Parameter | Hom kab mob | Kev cuam tshuam |

| ———————————————————————————

| Melt Temp | 280-320 ° C (PC) | Optical clarity |

| Txhaj Tshuaj | 1,800-2,200 bar | Fills micro-cov yam ntxwv |

| Lub sij hawm ntim | 8-12 vib nas this | Tiv thaiv cov cim dab dej |

Kev koom ua ke IoT: Real-time pressure sensors kho viscosity thaum sau (Kev lag luam 4.0 ua raws).

4. Sustainability Trends Reshaping kev lag luam

Cov ntsiab lus tseem ceeb: eco-friendly headlight pwm, siv cov khoom siv hauv tsheb teeb pom kev zoo *

- Kev Siv Tshuaj Siv Tshuaj: Eastman's PC rov ua dua tshiab tso cai 50% cov ntsiab lus rov ua dua yam tsis muaj xim daj.

- Pwm Txheej: CrN / AlCrN PVD coatings txuas lub neej pwm los ntawm 300%, txo cov khib nyiab steel.

- Kev txuag hluav taws xob: Txhua lub tshuab hluav taws xob txiav hluav taws xob siv los ntawm 60% vs hydraulic systems.

Cov Lus Qhia Txog Kev Cai: EU 2025 ELV Cov Lus Cog Tseg rau 95% rov ua dua lub teeb taub hau.

5. Cov thev naus laus zis tshiab los saib

Cov ntsiab lus tseem ceeb: AI hauv pwm tsim, 3D luam tawm tsheb pwm *

- AI Simulation: Autodesk Moldflow 2024 kwv yees cov kab txuas nrog 92% raug.

- Hybrid Tooling: Hardened inserts (HRC 54-56) ua ke nrog 3D luam tawm conformal txias.

- Ntse Moulds: Embedded RFID cim npe taug qab kev saib xyuas keeb kwm thiab hnav cov qauv.

Xaus

Mastering automotive headlight molding yuav tsum sib koom ua ke cov khoom siv science, precision engineering, thiab digital innovation. Raws li kev tsav tsheb tsav tsheb xav tau rau cov teeb pom kev zoo dua qub, kev siv cov tswv yim zoo tshaj no yuav ua rau cov tuam txhab ua lag luam nyob rau pem hauv ntej.

Hu rau Kev Ua: Xav tau kev tshuaj xyuas moldflow rau koj qhov project teeb taws tom ntej? [ Hu rau peb cov kws tshaj lij] kom muaj kev sib tham dawb.

Post lub sij hawm: Apr-01-2025