Pwm zoo muaj xws li cov hauv qab no:

(1) Cov khoom lag luam zoo: kev ruaj ntseg thiab kev sib haum xeeb ntawm cov khoom loj, qhov smoothness ntawm qhov chaw ntawm cov khoom, kev siv tus nqi ntawm cov khoom siv, thiab lwm yam;

(2) Kev pab lub neej: tus naj npawb ntawm cov voj voog ua haujlwm lossis tus naj npawb ntawm cov khoom tsim los ntawm pwm nyob rau hauv qhov chaw ntawm kev ua kom zoo ntawm cov khoom;

(3) Kev tu thiab tu cov pwm: txawm tias nws yooj yim rau siv, yooj yim rau demould, thiab lub sijhawm tsim khoom yog luv li sai tau;

(4) Cov nqi tu, tu ncua sij hawm, thiab lwm yam.

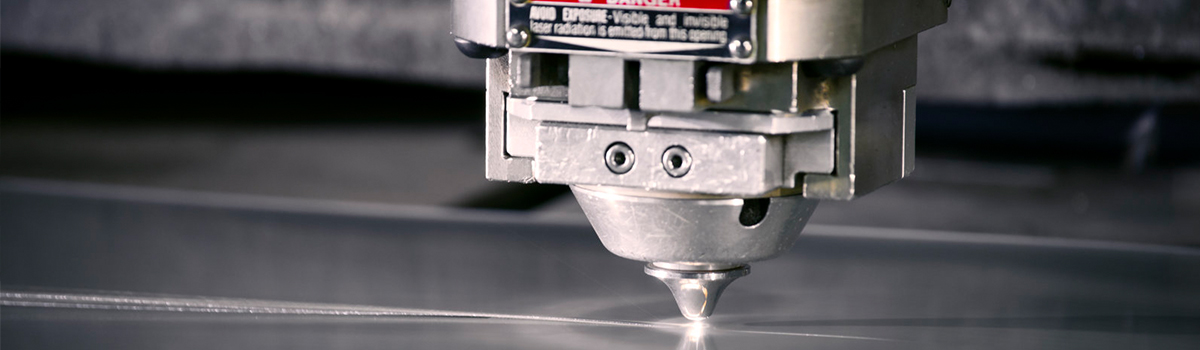

Txoj hauv kev los txhim kho qhov zoo ntawm cov pwm: kev tsim pwm yog ib qho tseem ceeb hauv kev txhim kho cov pwm zoo.Ntau yam yuav tsum tau xav txog, suav nrog kev xaiv cov khoom siv pwm, kev siv tau thiab kev nyab xeeb ntawm cov pwm pwm, kev ua haujlwm ntawm pwm pwm thiab kev kho pwm.Yooj yim, cov no yuav tsum tau xav txog thaum pib ntawm kev tsim.Kev tsim cov txheej txheem ntawm pwm kuj yog ib feem tseem ceeb ntawm kev ua kom cov pwm zoo.Cov txheej txheem kev ua haujlwm thiab kev ua tiav hauv cov txheej txheem tsim pwm kuj cuam tshuam rau lub neej kev pab cuam ntawm pwm.Qhov tseeb ntawm txhua qhov cuam tshuam ncaj qha cuam tshuam rau kev sib dhos tag nrho ntawm cov pwm.Ntxiv nrog rau kev cuam tshuam ntawm qhov tseeb ntawm cov khoom siv nws tus kheej, nws yog ib qho tsim nyog los txhim kho qhov tseeb ntawm cov pwm pwm los ntawm kev txhim kho cov txheej txheem machining ntawm cov khoom thiab txhim kho cov txheej txheem ntawm cov khoom siv hauv cov txheej txheem pwm sib tsoo..Nto ntxiv dag zog rau lub ntsiab molded qhov chaw ntawm cov pwm los txhim kho qhov chaw hnav tsis kam ntawm pwm qhov chaw, yog li txhim kho qhov zoo ntawm pwm.Kev siv kom raug thiab kev saib xyuas ntawm cov pwm kuj yog qhov tseem ceeb hauv kev txhim kho cov pwm zoo.

Piv txwv li, lub installation thiab debugging hom ntawm cov pwm yuav tsum tsim nyog.Nyob rau hauv cov ntaub ntawv ntawm cov neeg khiav dej num kub, cov hluav taws xob xaim hluav taws xob yuav tsum raug, thiab cov dej txias hauv Circuit Court yuav tsum ua tau raws li cov qauv tsim.Cov tsis muaj kev txhaj tshuaj molding tshuab, tuag casting tshuab thiab xovxwm nyob rau hauv zus tau tej cov pwm yuav tsum ua raws li tus tsim yuav tsum tau.thiab ntau ntxiv.Thaum siv pwm kom raug, pwm yuav tsum tau ua kom tsis tu ncua.Cov ntawv qhia, lub tes tsho qhia thiab lwm qhov chaw nrog cov txheeb ze txav ntawm cov pwm yuav tsum tau ntim cov roj lubricating.Rau txhua qhov ntawm forging pwm, yas pwm thiab tuag-casting pwm, Lub lubricant los yog pwm tso tawm tus neeg sawv cev yuav tsum tau siv rau saum npoo ntawm cov pwm ua ntej molding.

Nrog rau kev txhim kho hauv zej zog, qhov zoo ntawm cov pwm tau txais kev saib xyuas ntau dua.Nrog rau kev txhim kho ntawm kev tsim thiab tsim pwm thiab kev paub txog cov txheej txheem pwm tshiab, pwm zoo tau txais kev saib xyuas ntau dua.Kev ua tau zoo yog ib qho kev hloov pauv ntau zaus, thiab kev ua tau zoo yog kev txhim kho raws li cov cuab yeej pwm txhim kho.

Post lub sij hawm: Apr-23-2023