Kev sib tw sov yog qhov tseem ceeb hauv kev txhaj tshuaj molding.Raws li cov txheej txheem yas muaj kev txhawj xeeb, txoj hauv kev zoo los xaiv cov neeg ua haujlwm sov so rau cov khoom tsim nyog thiab ua kom cov neeg ua haujlwm sov so yog qhov tseem ceeb rau lawv cov txiaj ntsig los ntawm cov neeg ua haujlwm sov.

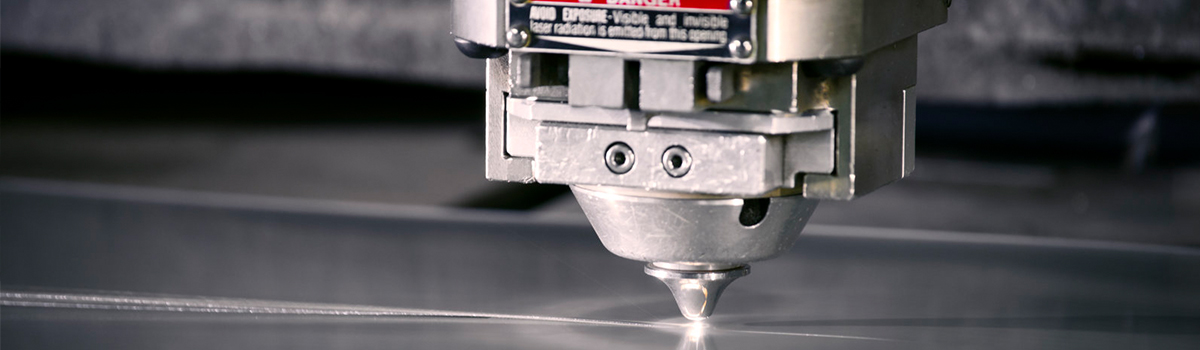

Lub tshuab ua kom sov (HRS) kuj yog hu ua qhov hluav taws xob dej kub, uas hloov lub taub dej khov rau hauv lub taub hau molten.Nws muaj pes tsawg leeg yog qhov yooj yim, feem ntau suav nrog cov manifold, kub nozzle, ntsuas kub thiab lwm yam.Nyob rau lub sijhawm no, lub phaj splitter tuaj yeem muab faib ua cov duab, X duab, Y duab, T duab, lub qhov ncauj thiab lwm yam tshwj xeeb raws li cov duab;qhov kub nozzle tuaj yeem muab faib ua lub nozzle loj, lub taub hau thiab lub koob valve nozzle raws li cov duab;tus tswj qhov kub thiab txias yog tswj tau Cov txheej txheem tuaj yeem muab faib ua hom tseem ceeb saib, hom plug-in thiab computer centralized tswj hom.

Hauv kev txhaj tshuaj molding txheej txheem, cov neeg ua haujlwm sov so ua haujlwm nrog cov pwm thiab ua lub luag haujlwm tseem ceeb heev.Piv txwv li, nyob rau hauv kev txhaj tshuaj molding ntawm ultra-nyias qhov chaw (xws li lub xov tooj ntawm tes roj teeb npog), nws yog ib qho yooj yim los tsim high-precision, high-zoo cov khoom los ntawm kev siv ntawm sov runners;rau kev txhaj tshuaj molding cov ntaub ntawv uas tsis zoo fluidity (xws li LCP), los ntawm kev siv sov tam sim no Txoj kev tuaj yeem txhim kho fluidity ntawm cov khoom thiab xyuas kom meej cov khoom zoo ntawm kev txhaj tshuaj molding.Rau qee qhov loj txhaj tshuaj molded, xws li lub bumper thiab lub qhov rooj vaj huam sib luag ntawm lub tsheb, lub rear cover ntawm lub TV, lub cua txias casing, thiab lwm yam., kev siv lub sov runner ua rau txhaj tshuaj molding nyuaj.Nws yuav tsum yog qhov yooj yim.

Hauv ntau kab noj hniav pwm txhaj tshuaj molding, qhov tsis muaj qhov sov so tsis tuaj yeem tsim txhua.Nws tuaj yeem hais tias qhov kev sib tw sov yog qhov zoo tshaj plaws technology los xyuas kom meej qhov sib npaug ntawm tus khiav.Vim lub shearing quab yuam ntawm cov yas nyob rau hauv lub ndlwg channel, tsis muaj teeb meem yuav ua li cas tsim nyog lub geometric tshuav nyiaj li cas ntawm cov pwm, cov khoom tivthaiv tsim yog ib tug nyuaj ua kom zoo ib yam, tshwj xeeb tshaj yog rau cov pwm uas muaj ntau kab noj hniav, yog hais tias tus sov runner tsis siv. , nws yog tsim.Sab nraud ntawm cov khoom yuav sib dua li sab hauv.

Raws li cov txheej txheem plastics muaj kev txhawj xeeb, nws yog qhov pheej yig heev los siv cov neeg ua haujlwm sov kom ntev li ntev tau tias muaj qee qhov kev txhaj tshuaj molding.Qhov no yog vim cov neeg ua haujlwm sov so pab cov tuam txhab tshem tawm cov nozzles thaum txhaj tshuaj molding.Feem ntau, lub nozzle tsis tuaj yeem rov qab siv dua.Qee zaum, qhov hnyav ntawm lub nozzle yuav luag tib yam li qhov hnyav ntawm cov khoom.Yog tias siv cov tshuaj nozzle ib txwm siv, nws txhais tau tias cov khoom siv khib nyiab ntau npaum li cov khoom siv.Raws li qhov kev suav no, tom qab siv lub tshuab ua kom sov, nws tuaj yeem txuag tau 30% txog 50% ntawm cov khoom siv.Tsis tas li ntawd, qhov kev sib tw sov kuj tseem tuaj yeem pab txo qhov hnav ntawm cov pwm thiab ua kom lub neej ntawm pwm.Raws li ib txwm muaj, kev pabcuam lub neej ntawm cov pwm kub khiav yog ob zaug ntawm cov pwm nozzle nyias.

Txawm hais tias muaj pes tsawg leeg ntawm cov neeg ua haujlwm sov yog qhov yooj yim, txhua qhov khoom ua si lub luag haujlwm tseem ceeb.Feem ntau, cov neeg ua haujlwm sov ua haujlwm zoo muaj qhov xav tau siab rau kev npaj cov txheej txheem thiab cov ntaub ntawv.Rau thawj qhov sov-up ntws channel, xaiv cov cua sov thiab cov kab ntsuas kub yog tag nrho cov tuaj ntawm Kaus Lim Qab Teb.Tag nrho cov hlau siv yog imported los ntawm Nyiv.Cov no yog qhov yuav tsum tau ua ua ntej kom ntseeg tau qhov zoo ntawm cov neeg ua haujlwm sov.

Tsis tas li ntawd, tus neeg muag khoom sov so yuav tsum tau pab cov neeg siv khoom npaj thiab teeb tsa lub tshuab ua kom sov ua haujlwm raws li tus neeg siv khoom cov khoom yas thiab cov xwm txheej ntawm cov pwm siv.Xianrui tau ntsib cov kws tshaj lij kev sib tw sov los ntawm Kaus Lim Qab Teb uas tuaj yeem npaj cov kev daws teeb meem tsim nyog raws li cov neeg siv khoom cov khoom lag luam kom ntseeg tau tias cov neeg khiav dej num sov tuaj yeem siv zog siab tshaj plaws hauv kev txhaj tshuaj molding.

Post lub sij hawm: Apr-23-2023